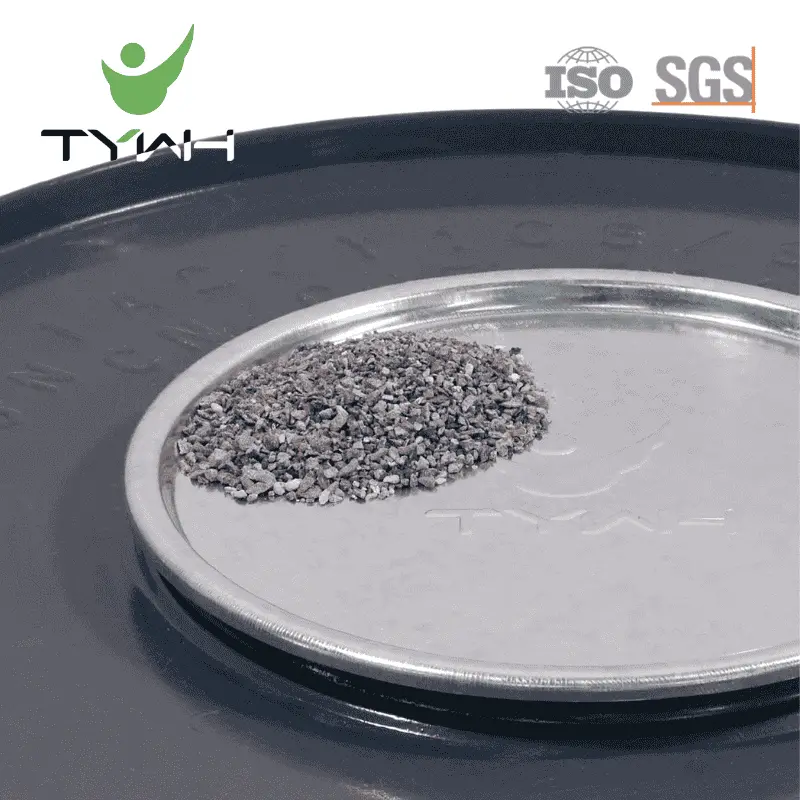

4-7 MM Calcium Carbide for Ductile Iron Desulfurization 50 KG/Drum | TYWH

TYWH IS THE WORLD'S LEADING SUPPLIER OF CALCIUM CARBIDE FOR USE IN THE DUCTILE IRON DESULFURIZATION

The graphite in ductile iron is spherical, a shape that inhibits cracking and thus enhances ductility, hence the name of the alloy. During production sulphur interferes with the spheroidisation process and inhibits the formation of ductile graphite. TYWH 1-7mm calcium carbide has become the preferred desulphurising agent for ductile iron due to its powerful desulphurising and deoxidising properties.

Si≤2%, Fe≤0.2%, P≤0.02%, S≤0.2%

TYWH Use Fully Automatic Production Process and Strict Inspection Process To Strictly Control the Impurity Content Index: Si≤2%, Fe≤0.2%, P≤0.02%, S≤0.2%.

pRODUCT DETAIL

|

1-7mm Calcium Carbide |

|||||

|

TYWH's quality standard is based on Chinese national standard GB10665-2004, with even stricter criteria applied to ensure superior quality. |

|||||

|

Quality Standard |

Gas Yield |

Size percentage |

PH3 %(V/V) |

H2S %(V/V) |

Ash,% |

|

TYWH Standard |

≥260 L/KG |

≥90% |

≤0.04% |

≤0.04% |

≤1% |

|

GB 10665-2004 |

≥260 L/KG |

≥85% |

≤0.08% |

≤0.1% |

≤5% |

CERTIFICATE

Palletizing

We support palletizing services and can palletize and pack according to your needs.

The relationship between the gas yield and calcium carbide is as following. |

||||||||

CaC2 (%) |

63.14 |

68.52 |

72.54 |

73.89 |

75.2 |

76.57 |

77.91 |

80.6 |

Gas Yield(L/Kg) |

235 |

255 |

270 |

275 |

280 |

285 |

290 |

300 |