Use of Calcium Carbide 7-15mm Calcium Carbide Wholesale - TYWH

Product Overview

Certainly! Here is the summary based on the detailed introduction of the product "Use of Calcium Carbide 7-15mm Calcium Carbide Wholesale - TYWH":

Product Features

**Product Overview**

Product Value

TYWH’s use of calcium carbide is an advanced and improved design that overcomes the limitations of older products. It is highly recognized and widely applied in various industries, particularly in steel production. The product’s development is backed by a professional quality control (QC) team ensuring high quality and reliability.

Product Advantages

**Product Features**

Application Scenarios

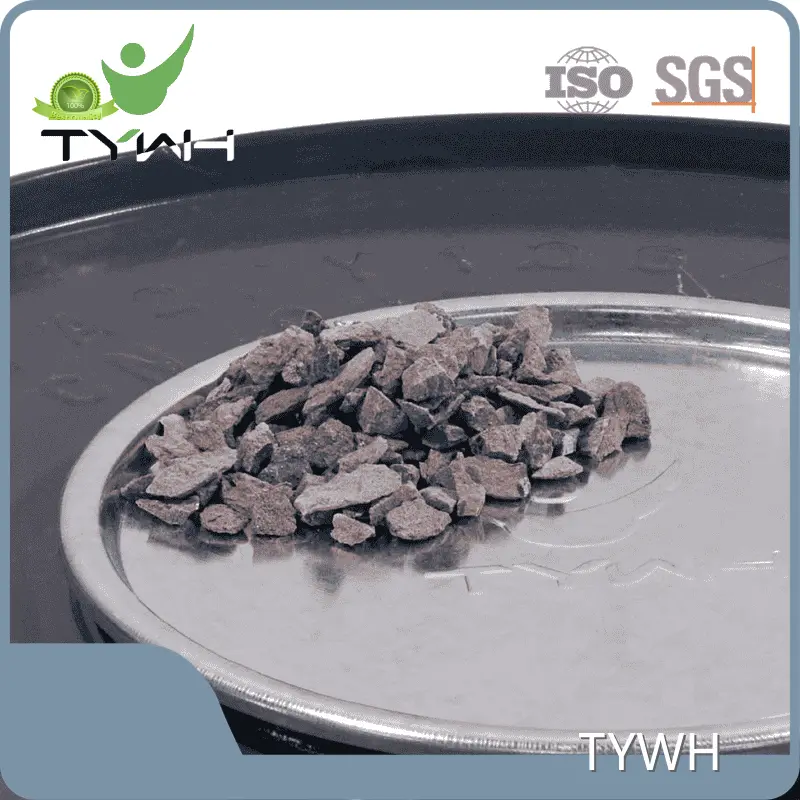

- Particle size: 7-15 mm

- High purity with controlled impurity levels: Si ≤ 2%, Fe ≤ 0.2%, P ≤ 0.02%, S ≤ 0.2%

- Manufactured using fully automatic production lines and strict inspection processes

- Large-scale capacity with 8 automated production lines producing up to 10,000 tons per month

- Supports customized packaging options like woven bags and steel drums for safe transportation

**Product Value**

This calcium carbide product offers powerful desulfurization and deoxidization properties, essential for producing high-performance steels such as low sulfur steel, alloy steel, and casting steel. Its consistent particle size and stable quality contribute to efficient and reliable industrial processes, reducing impurities and enhancing steel quality.

**Product Advantages**

- Industry-leading supplier with advanced production technology

- Strict impurity control ensuring product purity and performance

- Large-scale manufacturing capacity ensures product availability and consistency

- Custom packaging options improve transportation safety and customer convenience

- Highly recognized and praised by customers for broad application prospects

**Application Scenarios**

Primarily used in the steel smelting industry as a desulfurizer or deoxidizer in the production of:

- Low sulfur steel

- Alloy steel

- Casting steel

It supports the manufacturing of high-performance steel products by efficiently removing sulfur and oxygen impurities during the steelmaking process.